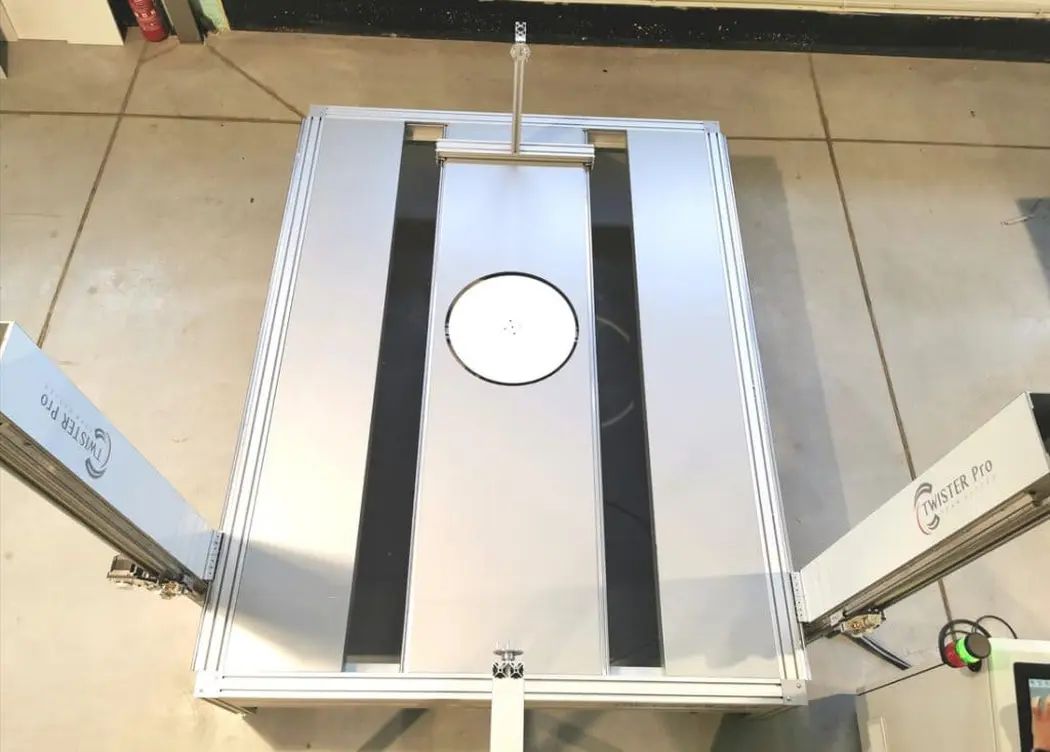

Hot wire foam cutter CNC machine

Hot wire foam cutter CNC machines are specialized CNC machines that allow for precise cutting in materials such as polystyrene, polystyrene, XPS polystyrene, EPS. Let’s check what these machines are characterized by and what functions they have.

Hot wire foam cutter

One of the most popular types of machines for cutting polystyrene are hot wire foam cutter CNC Such machines use resistance / shaped wires, which, combined with high temperature, allows them to cut any shapes in the material.

The hot wire foam cutter CNC machine can be intuitively operated using software provided by manufacturers or using a remote control with a display. Such plotters are modern machines that, using computer numerical control (CNC), can cut even the most complex 3D shapes very precisely.

The use of CNC control guarantees the user of the machine the highest quality, repeatability and precision of details and elements. The hot wire foam cutter CNC machine is suitable for various materials, such as extruded polystyrene, expanded polystyrene (XPS and EPS).

Due to the fact that hot wire foam cutter CNC machines for polystyrene are specialized machines, manufacturers can adjust the machine to the needs of a specific customer and company. Among other things, you can adjust things such as the method of cutting, format, number of resistance / shaped wires and various additional functionalities.

Depending on your production needs, you can find small devices for laboratories, small workshops as well as large machines and production lines for industrial applications.

Hot wire foam cutter CNC machines will work in various industries:

- architecture

- construction

- scenography

- film and market decorations

- shop windows

- stands at the fair

Thanks to such a plotter, you can create various interesting elements in a relatively short time that find their practical application in the industries listed above. However, these machines can be used to create various structures, elements or details, so they can be used in many other industries. Pneumatic, spring or electric tension of plotters allows for efficient cutting process.

The equipment and functions of hot wire foam cutter CNC machines vary depending on the specific model, but the most important of them are:

- independent arm movement

- swivel tables

- lathes - possibility of installing additional ones

- possibility of cutting using several resistance wires

- shaped wires for cutting complex shapes

Hot wire foam cutter CNC machine for polystyrene and styrodor

The hot wire foam cutter CNC machine for polystyrene is great for this material and its various varieties. By equipping the machine with a lathe, it is possible to achieve various shapes such as columns, balusters, solids of revolution, curly shapes, threads, longitudinal cuts. The lathe in which the hot wire foam cutter CNC machine is equipped can work on both resistance and shaped wire, for spatial cuts.

If you have individual needs and parameters that differ from the available models, it is worth asking the manufacturer about the possibility of modification. Most of the functions or parameters can be adapted to specific needs.

A hot wire foam cutter CNC machine for polystyrene can cut virtually any, even the most unusual shape from polystyrene, XPS or EPS. The rotary table that the machine is equipped with makes it easy to cut 3D models as well as flat 2D shapes into an irregular or symmetrical shape. It provides unlimited machining possibilities because it has a reliable and accurate rotating mechanism.

CNC foam cutting machine

The advantage is that the hot wire foam cutter CNC machine can work with files in popular formats such as EPS / AI, RAW 3D, dxf, plt. Independent movement of 4 axes allows you to cut complex shapes taking into account the perspective. Tension and heating can be controlled from the software. Just getting started with a plotter is easy because the manufacturer usually offers training on how to work on such a machine.

Hot wire foam cutter CNC machines are usually based on a solid construction that guarantees long-term durability and preservation of its parameters. The touch-screen computer that the machine is equipped with allows for convenient and intuitive operation. From the advantages of hot wire foam cutter CNC machines, you can definitely distinguish their solid construction, which guarantees a long life of the machine.

Autor: Materiał partnera

Przydatne dane teleadresowe

- Centrum Kształcenia Zawodowego w Chrzanowie – kontakt, godziny otwarcia i dojazd

- Powiatowe Centrum Kształcenia Ustawicznego w Chrzanowie – kontakt, godziny otwarcia, dojazd i strukturę jednostki

- Urząd Statystyczny w Krakowie Oddział w Chrzanowie – kontakt, godziny otwarcia, dojazd i strukturę jednostki

- Nadleśnictwo Chrzanów w Chrzanowie – kontakt, godziny otwarcia, dojazd, strukturę jednostki i sprawy online

- Powiatowy Ośrodek Wsparcia Dziecka I Rodziny w Chrzanowie – kontakt, godziny otwarcia i dojazd

- Powiatowy Zarząd Dróg w Chrzanowie – kontakt, godziny otwarcia, dojazd, strukturę jednostki i sprawy online